remixing materials

This biomaterials crash course spanning a few weeks was a main component that shaped my MDEF journey. It really opened my eyes to a completely new world of possibilities. Initially, some of my colleagues were somewhat acquainted with this rise in exploration of new materials but this was my first time being exposed to it. During Term I, I had my mind set on working solely with technology, however, the Remixing Materials course significantly diverted my journey into another destination.

JAN 20

First off, we had our introductory session with Lara Campos, who gave us an overview of her practice, her explorations with new materials and what types of careers or “jobs” these new explorations could complement. Unfortunately, I was still not in Barcelona at that time as I had COVID and had to extend my stay in Lebanon. However, I connected with a few of my colleagues who gave me a summary of this first session.

Lara also shared samples of her work with the class and announced that the next session would be a hands-on session where we would get to try things ourselves.

JAN 27

Back in Barcelona, covid-free, ready to get my hands dirty. In the IAAC main hall, we sat down for a small lecture where Lara described to us some basic knowledge that she extracted from her experience with working with biomaterials. She shared an overview of the standard process of making biomaterials, going through the following steps:

- select ingredients

- weight & write quantities

- prepare mold/frame with fabric

- pour water slowly into powder

- cook at mid fire for 10-15 min or till boiling point and turn the fire down

- add plasticizer (glycerin/oil) and antibacterial (vinegar/esstential oil)

- add additives

- pour in frame

- leave it to dry completely (and to avoid uneven shrinking)

- remove from frame

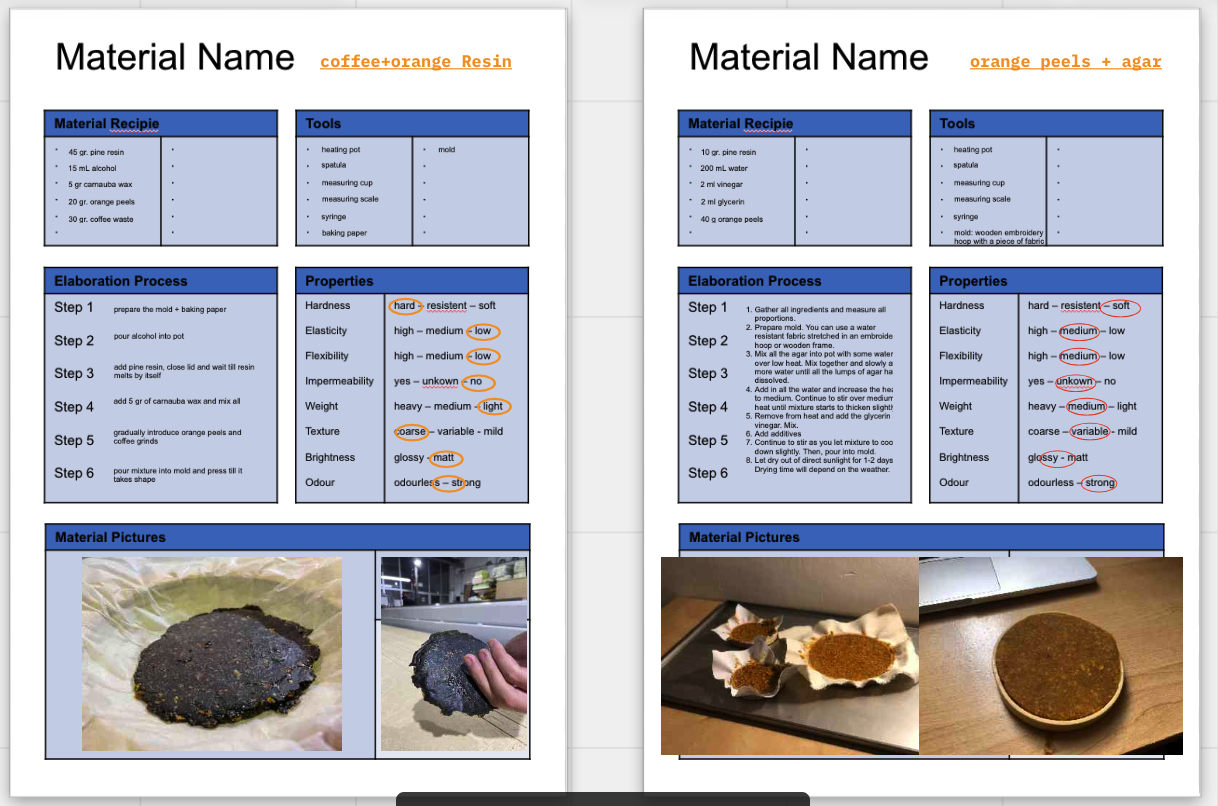

After that, Lara shared 3 main recipes, 2 of which are water soluble (glycerin/alginate based), and the other is not water soluble (pine resin based). The recipes are shown in the photo below.

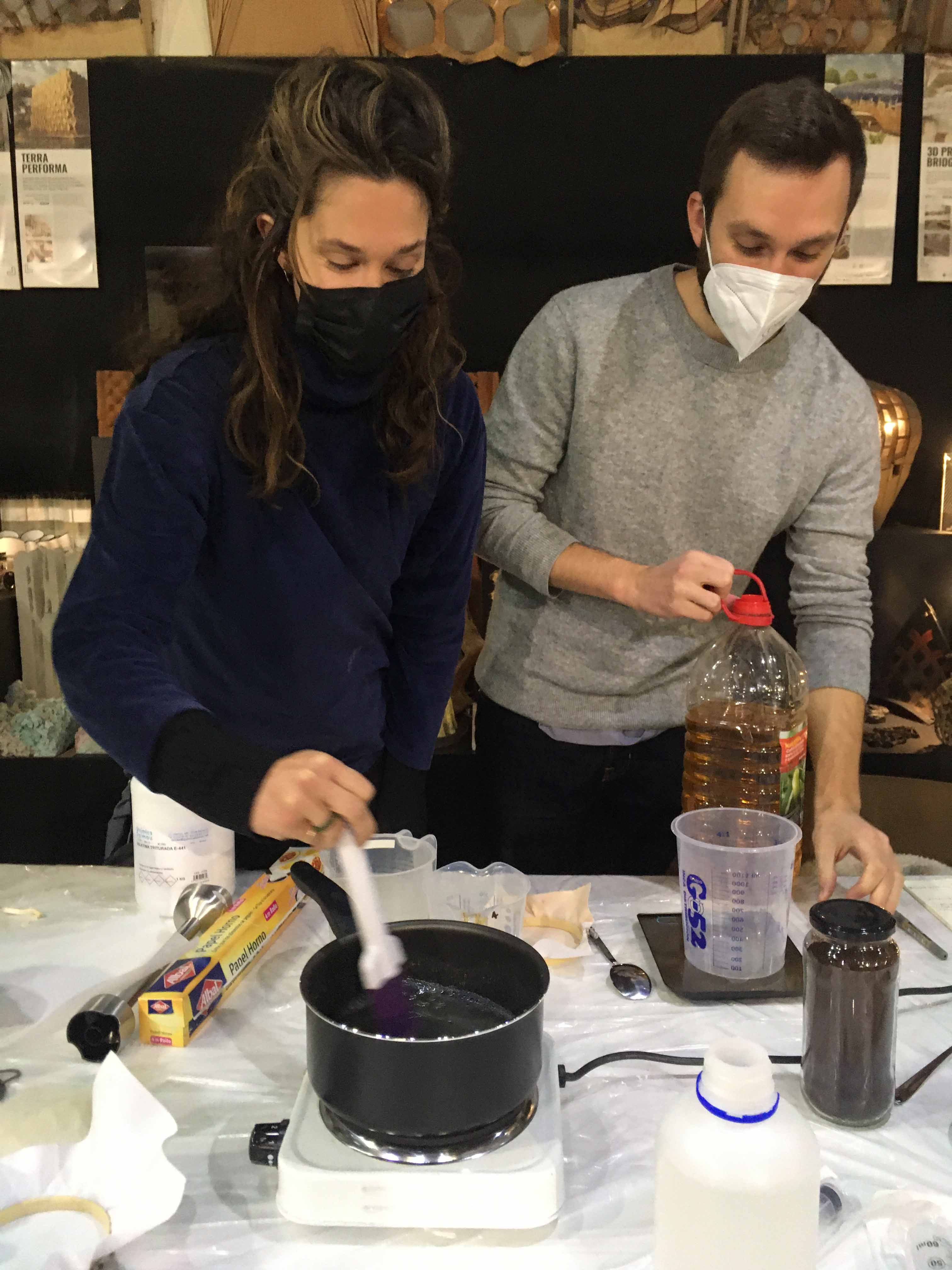

Together with Julia and Chris, we started going through our raw ingredients, what bio-waste we would like to try to have in our first bio-materials attempts, and which recipe we would like to delve deeper in. Below are a few iterations of the things we did with our agar agar/glycerin recipes and then the pine resin one.

For the agar agar recipe, we used broken down egg shells as our food waste, we also tried other things as well, such as hair, wool, etc... And for the pine resin one, we went for coffee grinds and dried orange peels. While trying these results, we automatically favored this recipe; the pine resin is quick to dry out and take shape, which was more convenient for us to make different iterations and see what texture we would like to achieve (given the time management difficulties that come along with the MDEF schedule.)

FEB 3: Remix el Barrio

After all that we did with Lara Campos, we had to unfortunately say goodbye and move on to the other section of the Remixing Materials course. We had a testimony presented to us by Remix El Barrio, going through their journey with biomaterials and winning the S+T+Arts award as well as being recognized by SISCODE. They explained to us the experiments they carried out during 9 months that were facilitated by Fab Lab Barcelona and showed us some samples of their work. They also answered questions about how they plan to take this forward and explained to us some hardships they faced.

After that, Laura Freixas, who is part of Remix El Barrio, talked to us about some endeavors that she took on after the group’s success. She worked with alternative textile in the fashion industry, and also collaborated with PUIG on some alternative perfume packaging and also figured out a way to make cardboard marble (crazy, right?).

All these testimonies really planted the seed of exploring new materials in my head and quickly manifested in my interests and interventions in MDEF. Which I will share shortly after.

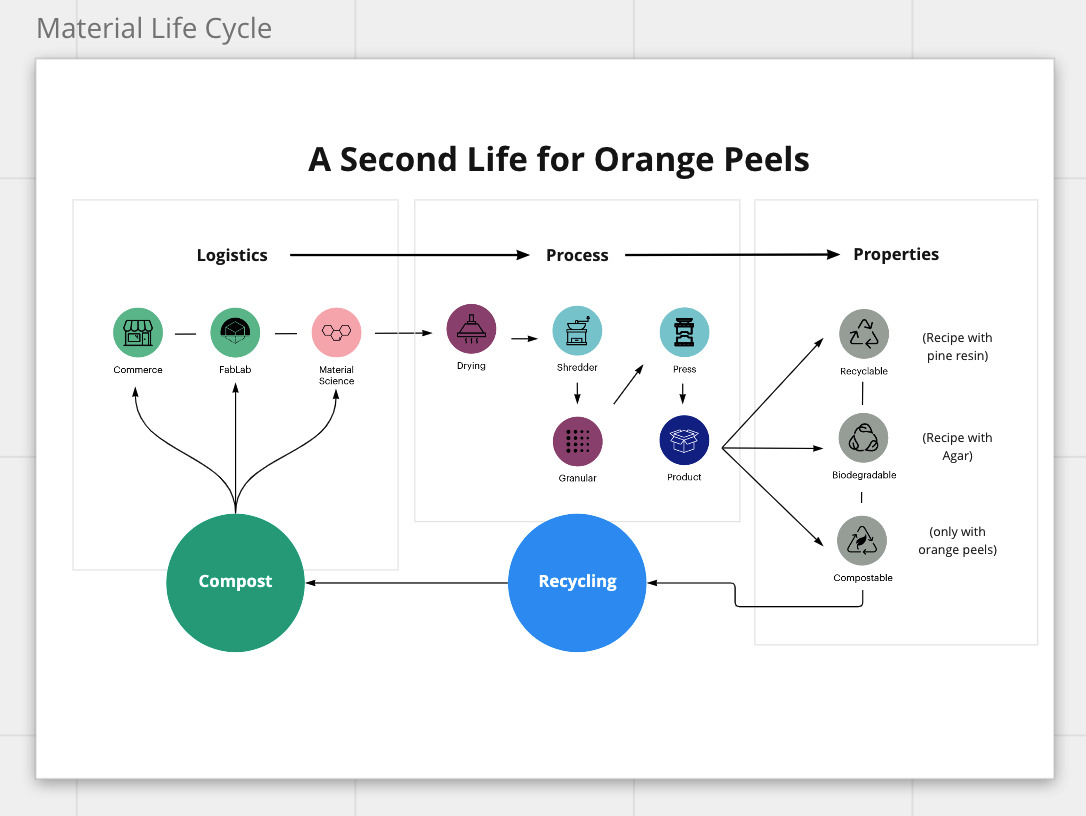

Laura’s workshop was more towards brainstorming and putting these explorations in context, thinking about stakeholders, fabrication methods, life cycles and circularity. She gave us tools and methods to instigate this process and let it perform naturally by going around locally to businesses, restaurants, cafes, farms, etc... and asking them about the type of waste they produce and whether they distribute and divide it or not.

Still on the same team with Julia and Chris, we decided to look around and find a place in Poblenou that produces orange peels and propose to them some multi-use plastic alternative kitchenware (specifically bowls, plates, cups) made out of biomaterials and using the main component which is orange peels. We eventually found out a restaurant/cafe called Santagloria in El Rambla del Poblenou which produces orange waste, so we took a bag of waste of that day and dried the orange peels.

This process was more or less difficult specifically to our group since at some point, both of my team mates had been experiencing covid symptoms and there wasn’t much that we were able to do on the ground. However, we handled the research bit quite nicely and organized our thoughts here on this Miro board.

The next plan was to create wood molds of bowls using the CNC machine in order to press some bowls and see what iterations we would have to make with the recipe and if the whole process is sustainable enough, taking into consideration the amount of waste that goes into these processes as well as the energy used to cook and transform these materials.

We made 2 iterations of the coffee+orange plate, the second worked way better and now it is in use. We are also planning to keep making more and trying out new recipes.

FEB 10

To wrap up the course (but definitely not the biomaterials practice), we had to make somewhat of an exposition/show and tell of what each group did and what was their purpose and talk briefly about the experiments that were done and the failures and successes. This part of the course was very interesting, as none of the groups really thought the same and everyone had something very innovative and interesting.

EXTRA: FABLAB Microchallenge 1

Inspired and moved by the biomaterials workshop, we took the practice and implemented parts of it as part of our first microchallenge, together with Kai, where we decided to make kids’ stamps out of biomaterials and recycled plastic. It was very fun to go through this and have a whole week as we experimented different types of molding and casting and we married some of the process with digital fabrication, specifically laser cutting and used some agar agar recipes for the “stamp” part of our artifact. It was nice to take into consideration the different factors, such as the waste that goes into this and the time and process of the whole experiment and when’s the best time to mold it / cut it as these products shrink significantly after drying.

You can find more of this challenge and the process here.