✅ c5: 3d printing

For this week’s fab course, we went over 3D printing and scanning. To start off, as usual, we went briefly through the history of 3d printing, how it developed and how it came to be what it is today.

We went through some main qualities and characteristics of 3D printing that set it apart from other digital fabrication methods.

Then we went into some basic procedures to prepare our 3d models for printing in terms of technicalities, like exporting the 3d models and (.stl) files and then passing it through “Slicer” to determine the some specifications that are necessary and vary hugely from each other, such as the directions of the lines, the hollowness of the object, the line thickness as well as other things. And then finally sending the file to the 3d printer.

For the assignment, we had to design and 3D print an object of our choice within the dimensions of 70x70x70 mm.

Initially, I had seen one of those avocado seed boats that can be 3d printed in order to hold avocado seeds during the first phase of rooting and growing. However, I watched some people complain about these boats as they come to find the boat has sunk with the avocado seed, which would ruin the process. Moreover, this “boat” would require a container bigger than a cup, which isn’t very efficient in terms of space.

For that reason, I took to Fusion and decided to make 2 iterations of this boat that could fit better in a cup and wouldn’t sink in the water and try them to see if they would work.

My first attempt is basically ‘the wheel’, which would hold the seed in the middle and would be pushed into the cup and locked in a way that it wouldn’t move later.

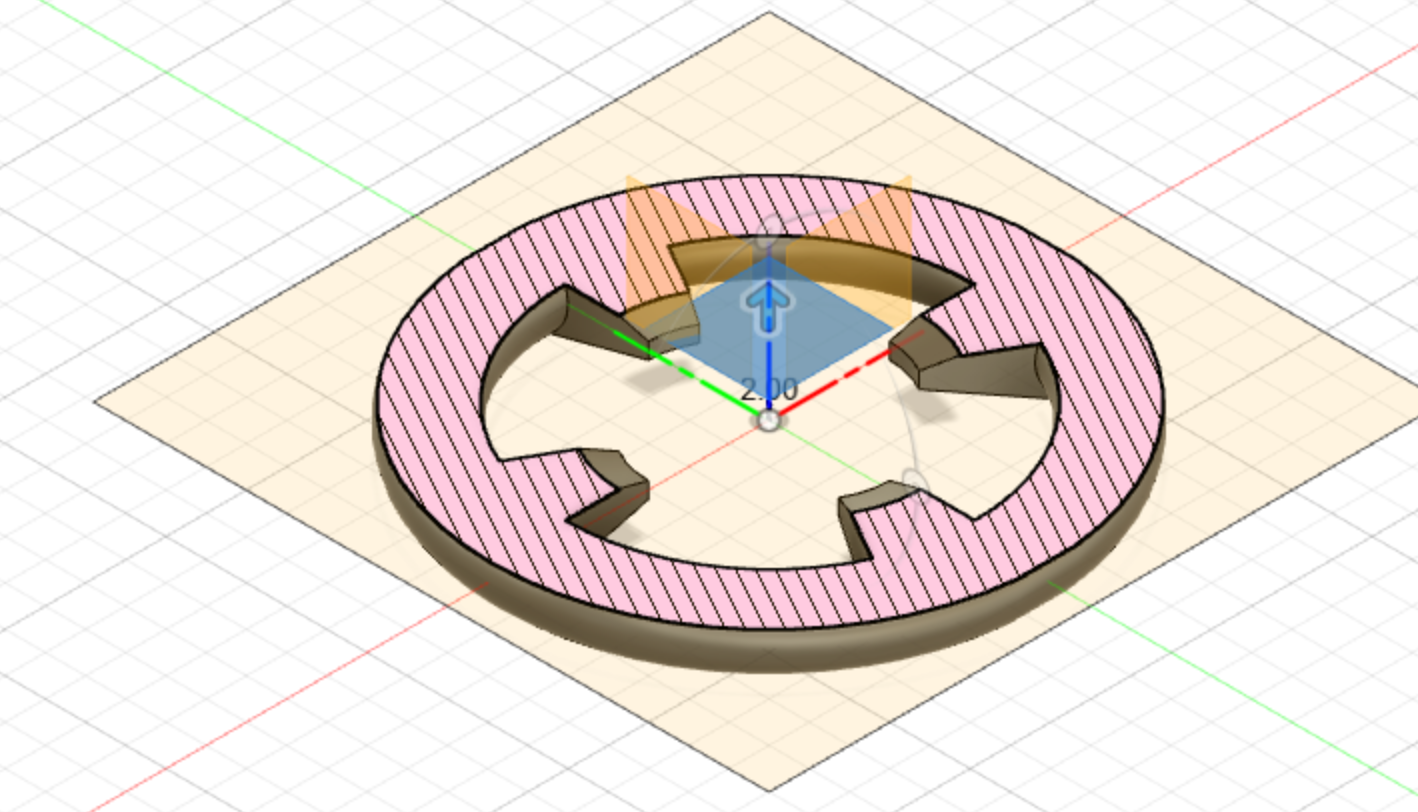

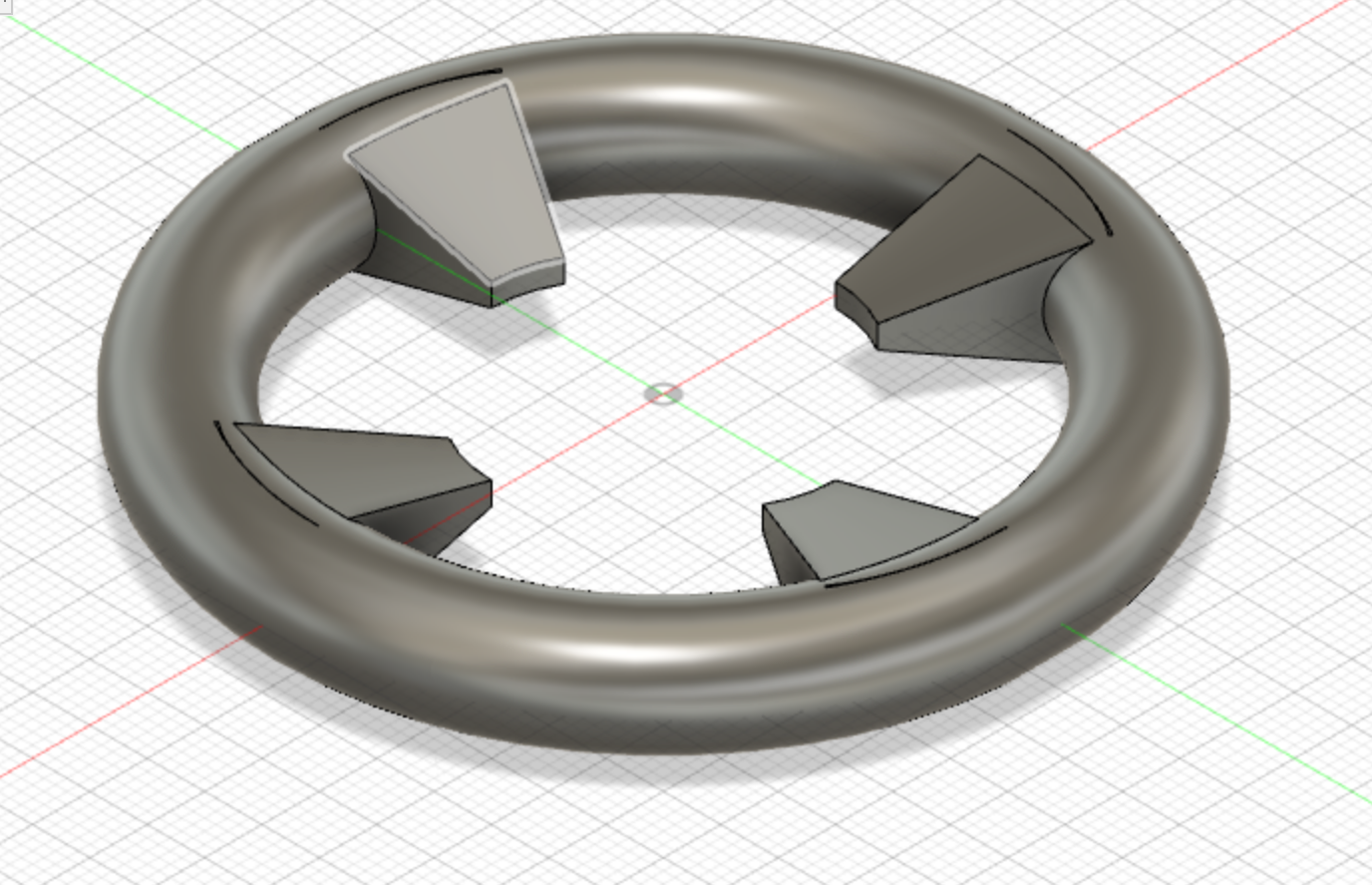

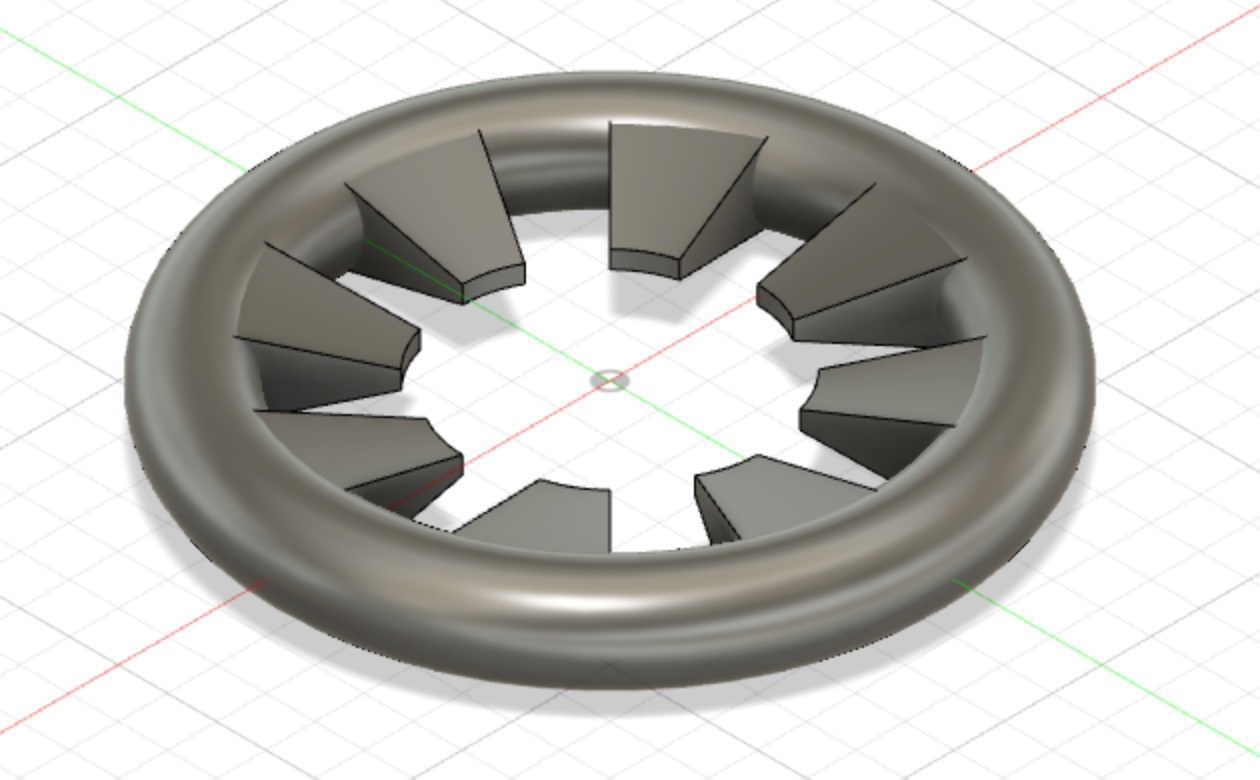

Here are some attempts:

/4 teeth/

/8 teeth/

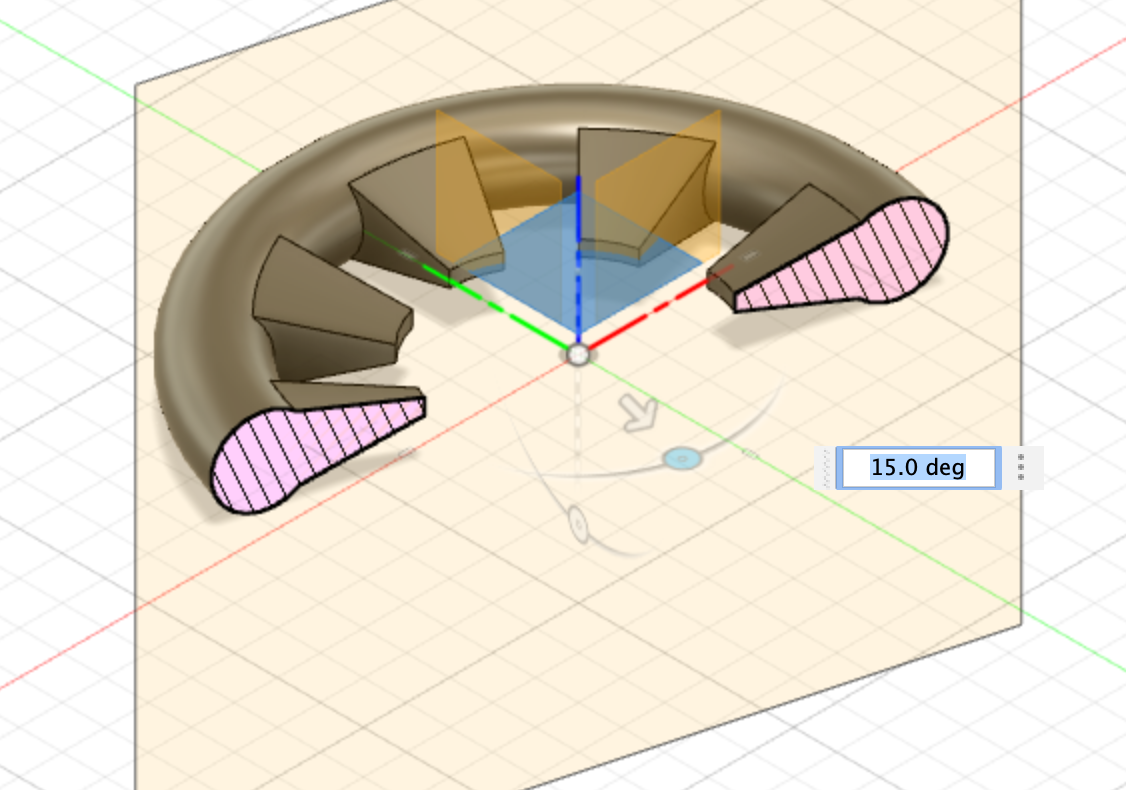

For the second iteration, I decided to make something that would sit on the rim of the cup, and would work with many cup sizes.

See the model below.